| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | JAGUAR |

| Model Number : | R10 |

| Certification : | CE ISO9001 |

| Price : | Negotiation |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 2 + Set + per Day |

Dual Track Hot Air Lead-free Reflow Oven With Central Support Model

JAGUAR R High-end series was designed for high standard

applications, such as Semi-conductor, automobile, military related

& etc…, which provides optimized lead-free processing, with high

precision of heating and cooling, low power & nitrogen consumption,

R series is favored by senior application customers.

Specification:

| Model | JAGUAR R10 | |

Heating System | Number of heating zones | Top 10/Bottom 10 |

| Number of cooling zones | Up 3 Bottom 3 | |

| Heating Passage | 3891mm | |

| Heating Style | Hot air | |

| Cooling Style | Air Oven: Forced air | |

| Exhaust Volume | 10m³/min * 2 vanes | |

Conveyor System | Max. Width of PCB | 420mm |

| Mesh belt width | 500mm | |

| Conveyor Direction | L→R(or R→L) | |

| Process Height | 900±20mm | |

| Conveyor style | Mesh and chain | |

| Conveyor speed | 0-2000mm/min | |

| Auto/manual Lubrication | Standard | |

| Fixed Track | Front track fixed(option: rear track fixed) | |

| Product Clearance | Top and bottom 25mm | |

Control system | Power supply | 5 cables 3 phase 380V 50/60Hz |

| Total consumption | 50kw | |

| Startup consumption | 48kw | |

| Steady consumption | 10KW | |

| Ramp up time | About 20 mins | |

| Temp. set-point range | Room temperature-300℃ | |

| Temp. control method | PID close loop control & SSR driving | |

| Temp. control precision | ±1℃ | |

| Temp. deviation on PCB | ±2℃ | |

| Data storage | Process Data and status storage(80GB) | |

| Nozzle plate | Aluminum Alloy Plate | |

| Abnormal Alarm | Abnormal temp. (overtemp/low temp.) | |

| Board dropped alarm | Light Tower: Amber-warming, Green-normal, Red-abnormal | |

General | Dimension(L*W*H) | 6200×1650×1550mm |

| Weight | 2150KG | |

| Color | Computer grey | |

| Nitrogen content | 500-1000ppm | |

| No. | Spares Name | Brand | Origin |

| 1 | Heating Tube | Hotset | Germany |

| 2 | Intermediate relay | Schneider/CHNT(standard) | France/China |

| 3 | Contactor | Schneider/CHNT(standard) | France/China |

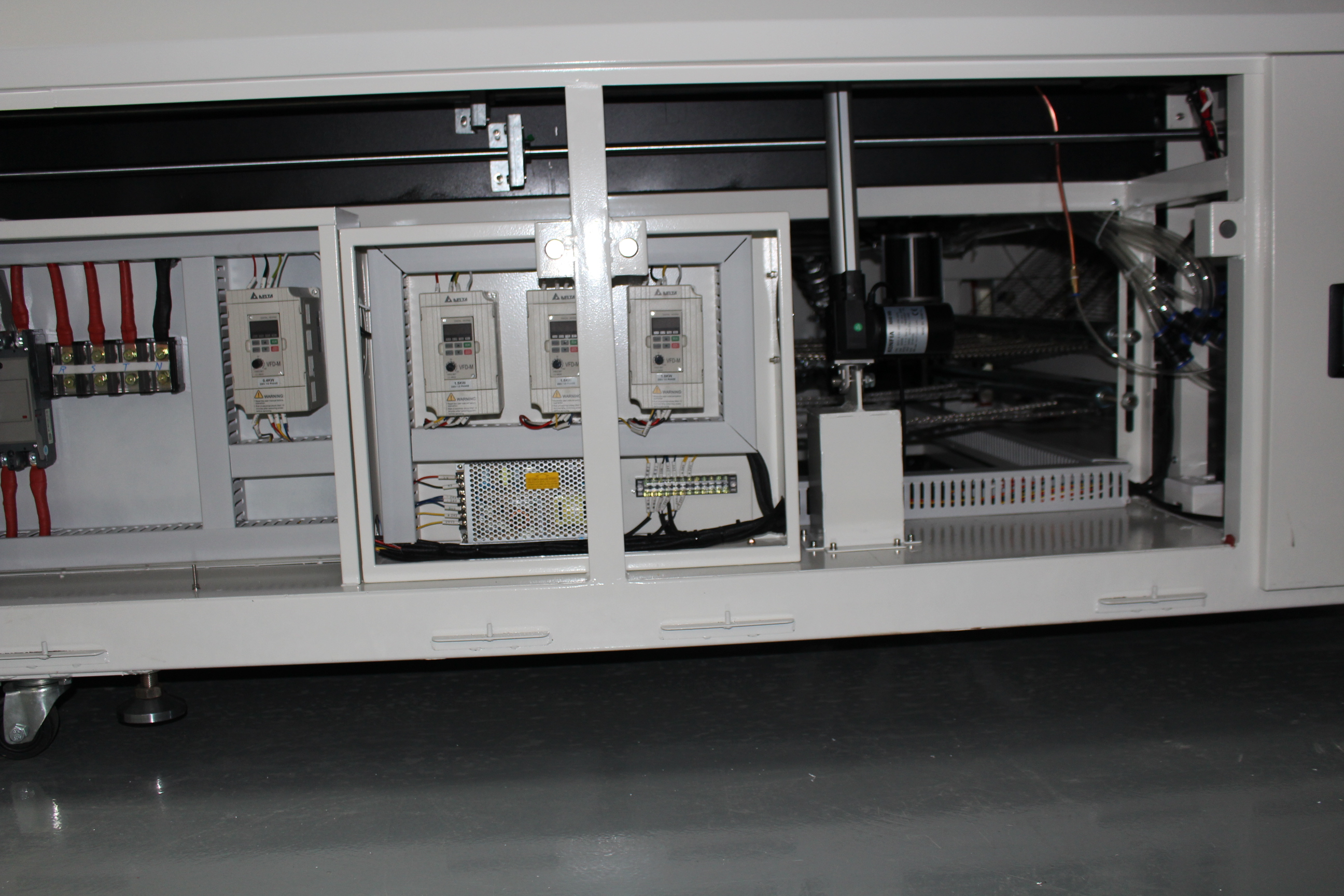

| 4 | Power supply | MW | Taiwan |

| 5 | Binding post | Phoenix | America |

| 6 | Inverter | Rockwell/Delta | America /Taiwan |

| 7 | Solid-state Relay | Carlo Gavazzi | America |

| 8 | Emergency button | Schneider | France |

| 9 | LED Tricolor light tower | Skoda | China |

| 10 | Conveyor motor/Tooth box | Panasonic | Japan |

| 11 | High Temperature motor | Sanyue | Taiwan |

| 12 | Thermal fuse | Hotset | Germany |

| 13 | Connecting shackle | KMC | Taiwan |

| 14 | High temperature cable | Hotset | Germany |

| 15 | Fan | Sunon | Taiwan |

| 16 | Mesh belt | KMC/TSUBAKI | Taiwan/Japan |

| 17 | Display | Lenovo | China |

| 18 | Computer | Lenovo | China |

| 19 | PLC | Siemens | Germany |

| 20 | Chain | KMC/TSUBAKI | Taiwan/Japan |

| 21 | Guide rail | JAGUAR | China |

Reliable Heating Zone Structure

※ Patented air management system to make hot air convection more efficient and faster thermal compensation

※ Nozzle plate made from 8mm thick aluminum plate

※ The longer heating zones to ensure perfect profile matching, meantime can get high production efficiency

Reliable Control system

※ Siemens PLC+Industrial PC with precise controlling unit and stabilized performance

※ PID close loop control + SSR driving to ensure the temp. control precision up to ±1°c and the temp. Deviation on PCB up to ±1.5°c

Reliable Conveyor System

※ The rail is dealt with hardened process to make it more stability

※ The conveyor chain adpoted with single Pin-plate design, simple and pratical

R10 Installed in Our Customer's Factory

|