| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | JAGUAR |

| Model Number : | TOP450 |

| Certification : | CE ISO |

| Price : | To be negotiate |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 50sets per month |

| Delivery Time : | 10-15 Working Days |

JAGUAR N450 Lead-free Hot Air Wave Soldering External Flux Sprayer Style

Specification:

| Model No. | JAGUAR N450 |

| Numberof Heating Zones | 4 |

| Length of Heating Zones | 2000mm |

| Total/Steady Consumption | 30KW/8-11KW |

| Air Supply | 0.5MPa |

| Preheating Style | Hot Air |

| Preheating Consumption | 220V 8KW |

| Controlmethod | PC+PLC |

| Rangeoftemp.setpoint | Room temperature---300ºC |

| Preheatingtime | About10-15mins forsetting150ºC |

| SolderApplication | Lead-free/Sn-Pb |

| Solderpotcapacity | 420KG |

| Solderpottemperature | 300ºC |

| Solderpotmaterial | Cast Iron Ceramic Coating/TA1 Titanium/316 Stainless Steel |

| Heater consumption | 380V8KW |

| Soldertemp. controlmethod | PID+SSR |

| Wave motor consumption | 250Wx2pcs 220V |

| Waveheight Control | Inverter |

| Solder melting time | About180mins forsetting250ºC |

| PCBwidth | 30-350mm |

| Productclearance | Top120mm(option160mm)Bottom15mm |

| Conveyor speed | 0-2000mm/min |

| Process height | 750+/-20mm |

| Conveyor direction | L→R (R→Loptional) |

| Conveyor Inclination | 4-7º |

| Process widthadjustment | Manual |

| UPS | Option |

| Nitrogenstructure | Option |

| Fluxpressure/capacity | 3-5bar/6.5L |

| Weight | 1600KG |

| PowerRequirement | 3P5W,380/220V50Hz63A |

| Dimensions | 4500(L)*1420(W)*1750(H) |

1. Energy-saving, lead-free application, meet with environmental protection requirement and user friendly designed

2. Automatic power system, inverter control, automatic board in-load feature.

3. Flux sprayer using transverse Japanese spray nozzle and driving by stepper motor, spray range is selective, PLC controlled, accurate and reliable.

4. Flux recovery container drawer design, easy to clean.

5. Conveyor equiped 3 width adjustable screws, the conveyor transmission is more stable, no PCB falling risk.

6. Titanium solder fingers, high strengthened double v-groove with tin resistant

7. PID close loop controlled hot air pre-heaters, preheating system uses four independent temperature control so as to ensure the excellent heat preservation, temperature uniformity, temperature accuracy in ±2ºC.

8. Pre-heat passage modular design, environmental protection and safety, convenient for cleanup.

9. Solder motor adopts imported high frequency conversion motor with independent control, stable performance.

8. Solder pot's inpeller material is cast iron, never corrode, solder pot with oxidation jacket, low solder dross

11. Timer startup feature for solder pot, solder melted in within 90 minutes.

12. Automatic finger cleaner equipped.

13. With black box memory function, the machine can always store the SPC data, improve work efficiency.

14. Intelligent monitoring and alarm system ensure the stable performance and operators’ safety.

Features:

Flux spray system

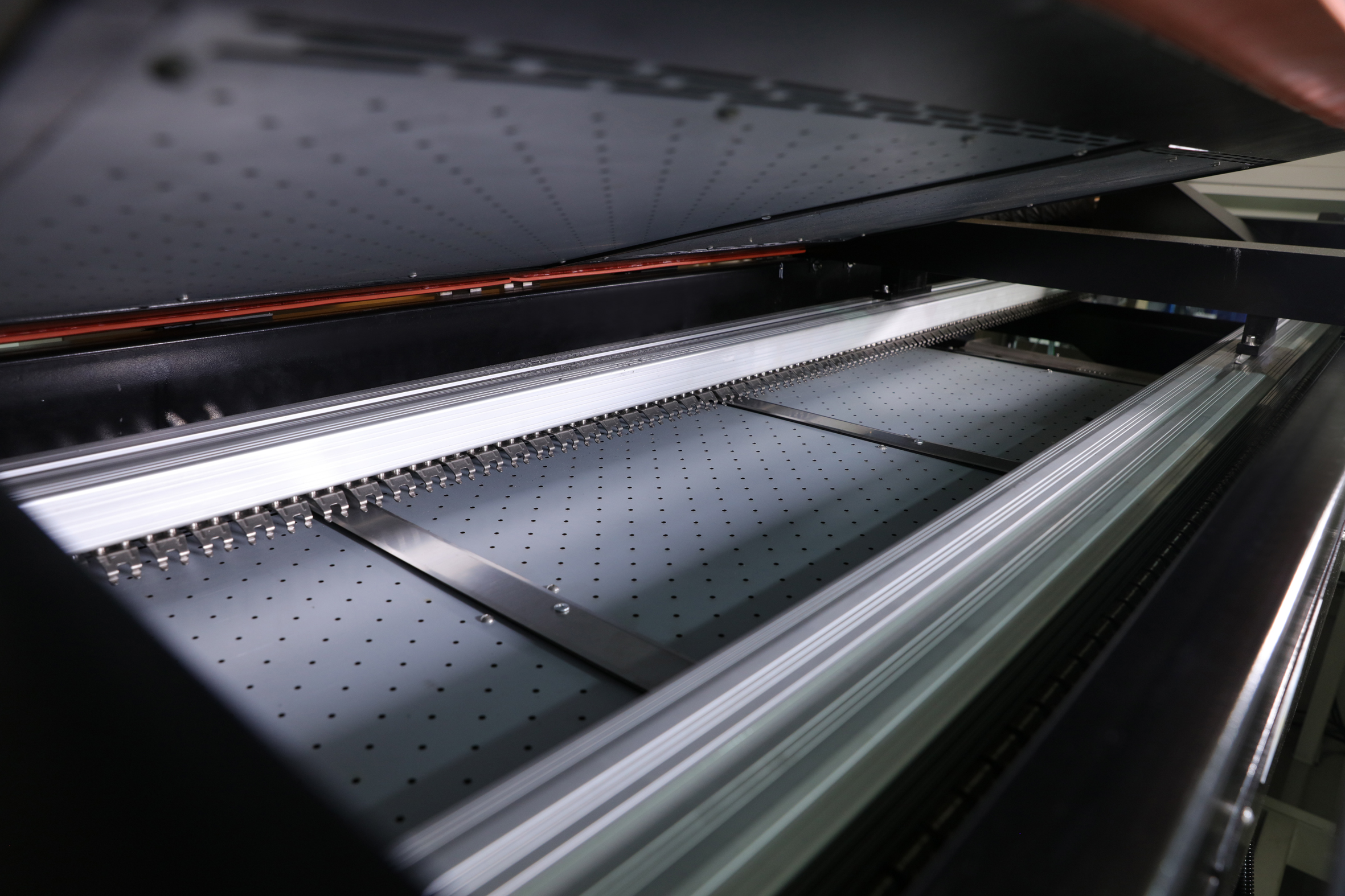

Conveyor System

Preheating System

Soldering System

Automatic Finger Cleaning System

Please contact me if you have need any machine!

|